(Peer-Reviewed) Laser additive manufacturing of Si/ZrO2 tunable crystalline phase 3D nanostructures

Greta Merkininkaitė ¹ ², Edvinas Aleksandravičius ³, Mangirdas Malinauskas ³, Darius Gailevičius ² ³, Simas Šakirzanovas ¹ ⁴

¹ Faculty of Chemistry and Geosciences, Vilnius University, Naugarduko Str. 24, Vilnius LT-03225, Lithuania

² Femtika, Sauletekio Ave. 15, Vilnius LT-10224, Lithuania

³ Laser Research Center, Physics Faculty, Vilnius University, Sauletekio Ave. 10, Vilnius LT-10223, Lithuania

⁴ Department of Chemical Engineering and Technology, Center for Physical Sciences and Technology, Sauletekio Ave. 3, Vilnius LT-10257, Lithuania

Opto-Electronic Advances, 2022-01-28

Abstract

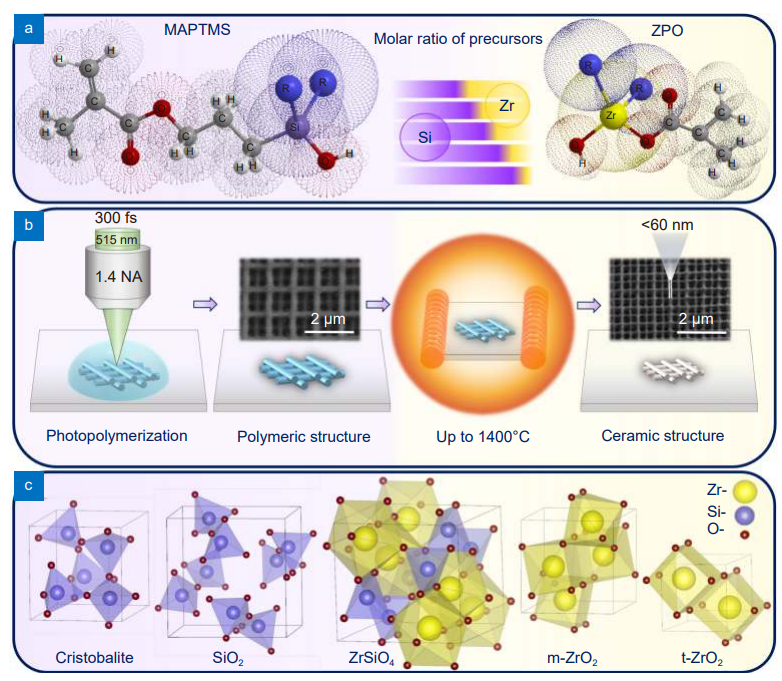

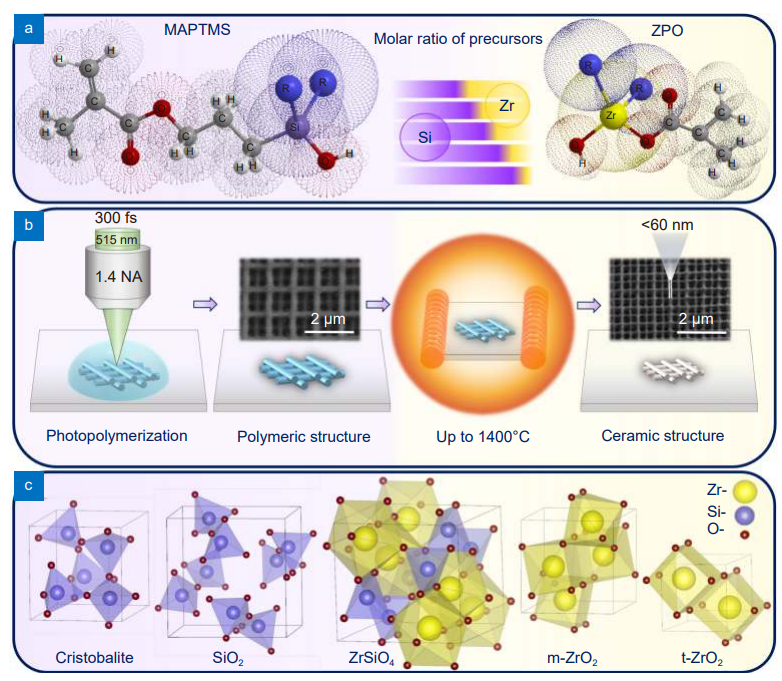

The current study is directed to the rapidly developing field of inorganic material 3D object production at nano-/micro scale. The fabrication method includes laser lithography of hybrid organic-inorganic materials with subsequent heat treatment leading to a variety of crystalline phases in 3D structures.

In this work, it was examined a series of organometallic polymer precursors with different silicon (Si) and zirconium (Zr) molar ratios, ranging from 9:1 to 5:5, prepared via sol-gel method. All mixtures were examined for perspective to be used in 3D laser manufacturing by fabricating nano- and micro-feature sized structures. Their spatial downscaling and surface morphology were evaluated depending on chemical composition and crystallographic phase.

The appearance of a crystalline phase was proven using single-crystal X-ray diffraction analysis, which revealed a lower crystallization temperature for microstructures compared to bulk materials. Fabricated 3D objects retained a complex geometry without any distortion after heat treatment up to 1400 °C. Under the proper conditions, a wide variety of crystalline phases as well as zircon (ZrSiO₄ - a highly stable material) can be observed.

In addition, the highest new record of achieved resolution below 60 nm has been reached. The proposed preparation protocol can be used to manufacture micro/nano-devices with high precision and resistance to high temperature and aggressive environment.

A review on optical torques: from engineered light fields to objects

Tao He, Jingyao Zhang, Din Ping Tsai, Junxiao Zhou, Haiyang Huang, Weicheng Yi, Zeyong Wei Yan Zu, Qinghua Song, Zhanshan Wang, Cheng-Wei Qiu, Yuzhi Shi, Xinbin Cheng

Opto-Electronic Science

2025-11-25