(Peer-Reviewed) A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion

Dawei Wang 王大为 ¹ ⁵, Huili Han ², Bo Sa 撒波 ¹, Kelin Li ¹, Jujie Yan 严菊杰 ¹, Jiazhen Zhang 张嘉振 ³, Jianguang Liu 刘建光 ³, Zhengdi He 何正娣 ⁴, Ning Wang 王宁 ⁴, Ming Yan 严明 ¹ ⁵

¹ Department of Materials Science and Engineering, and Shenzhen Key Laboratory for Additive Manufacturing of High Performance Materials, Southern University of Science and Technology, Shenzhen 518055, China

中国 深圳 南方科技大学材料科学与工程系 深圳市高机能材料增材制造重点实验室

² Department of Mechanical and Energy Engineering, Southern University of Science and Technology, Shenzhen 518055, China

中国 深圳 南方科技大学机械与能源工程系

³ COMAC Beijing Aircraft Technology Research Institute, Beijing 102211, China

中国 北京 中国商飞 北京民用飞机技术研究中心

⁴ Shenzhen Technology University, Shenzhen 518118, China

中国 深圳 深圳技术大学

⁵ Jiaxing Research Institute, Southern University of Science and Technology, Jiaxing 314031, China

中国 嘉兴 南方科技大学嘉兴研究院

Opto-Electronic Advances, 2022-07-27

Abstract

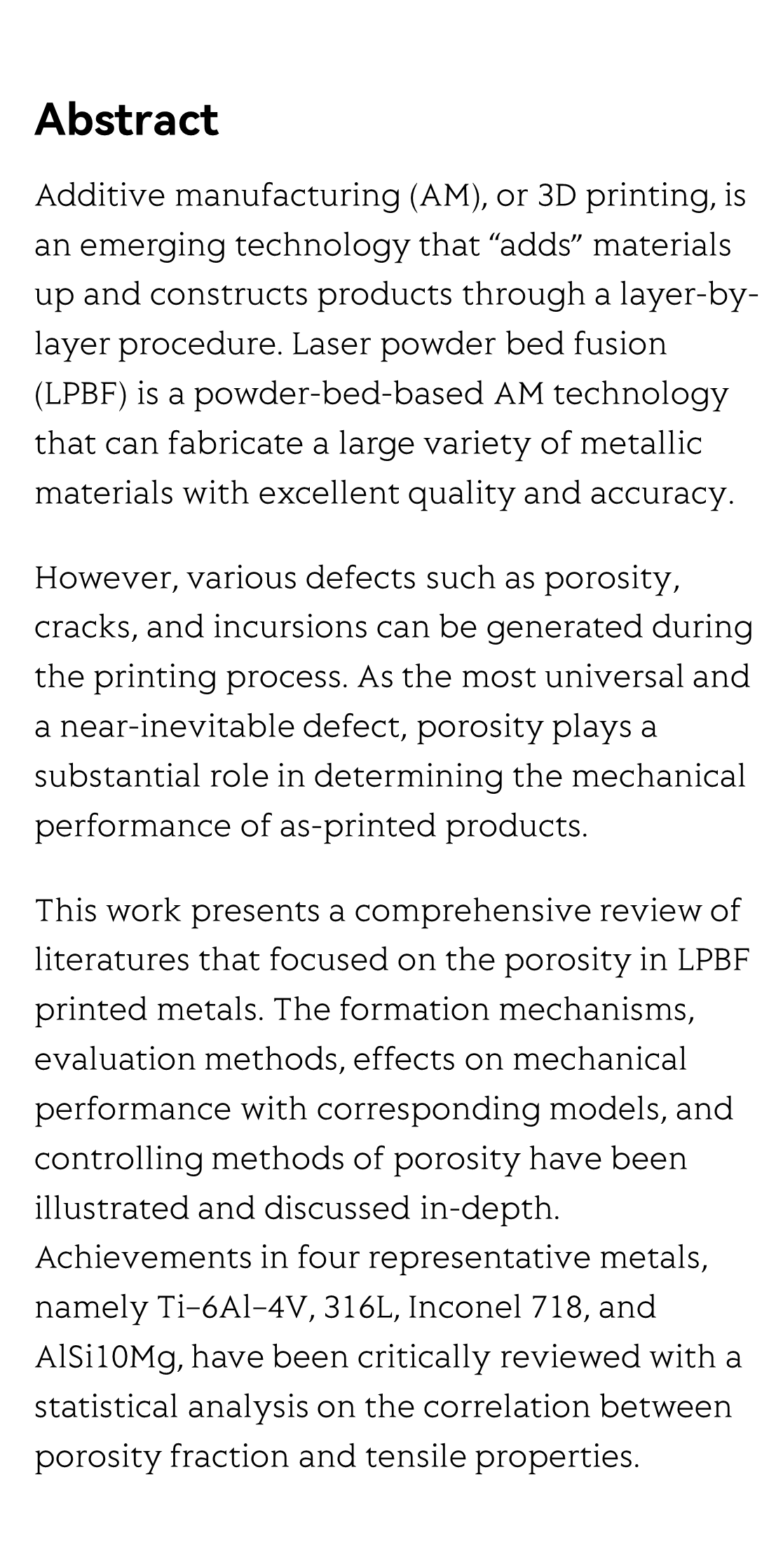

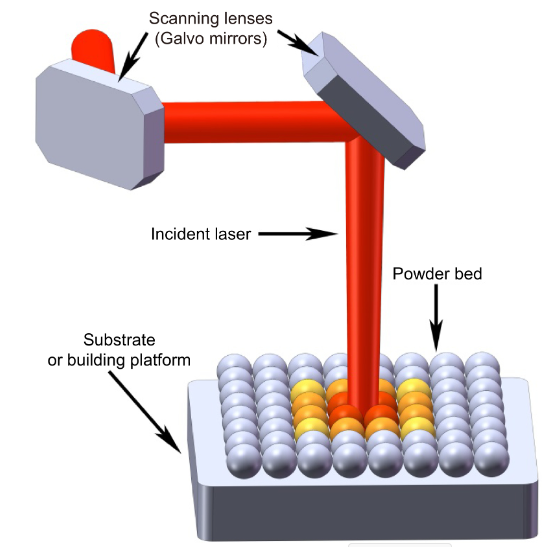

Additive manufacturing (AM), or 3D printing, is an emerging technology that “adds” materials up and constructs products through a layer-by-layer procedure. Laser powder bed fusion (LPBF) is a powder-bed-based AM technology that can fabricate a large variety of metallic materials with excellent quality and accuracy.

However, various defects such as porosity, cracks, and incursions can be generated during the printing process. As the most universal and a near-inevitable defect, porosity plays a substantial role in determining the mechanical performance of as-printed products.

This work presents a comprehensive review of literatures that focused on the porosity in LPBF printed metals. The formation mechanisms, evaluation methods, effects on mechanical performance with corresponding models, and controlling methods of porosity have been illustrated and discussed in-depth. Achievements in four representative metals, namely Ti−6Al−4V, 316L, Inconel 718, and AlSi10Mg, have been critically reviewed with a statistical analysis on the correlation between porosity fraction and tensile properties.

Ductility has been determined as the most sensitive property to porosity among several key tensile properties. This review also provides potential directions and opportunities to address the current porosity-related challenges.

Separation and identification of mixed signal for distributed acoustic sensor using deep learning

Huaxin Gu, Jingming Zhang, Xingwei Chen, Feihong Yu, Deyu Xu, Shuaiqi Liu, Weihao Lin, Xiaobing Shi, Zixing Huang, Xiongji Yang, Qingchang Hu, Liyang Shao

Opto-Electronic Advances

2025-11-25

A review on optical torques: from engineered light fields to objects

Tao He, Jingyao Zhang, Din Ping Tsai, Junxiao Zhou, Haiyang Huang, Weicheng Yi, Zeyong Wei Yan Zu, Qinghua Song, Zhanshan Wang, Cheng-Wei Qiu, Yuzhi Shi, Xinbin Cheng

Opto-Electronic Science

2025-11-25